Village Hall

Replica Building

Built 1979/1980

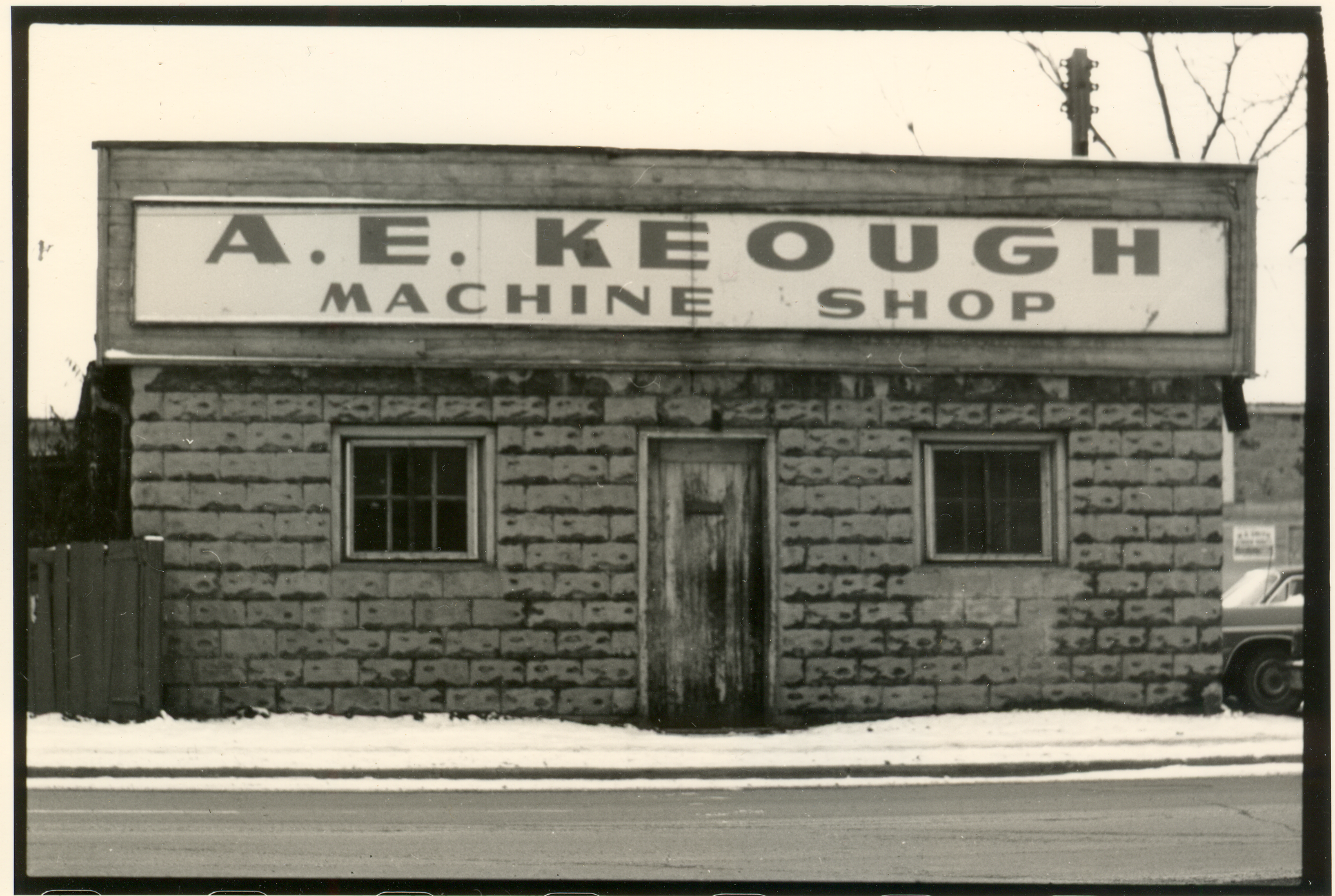

Displays a portion of the A.E. Kough Machine Shop Collection

This building was originally built to house the Keough Machine Shop collection dating from the early 20th century. Today it is used as rental and programming space at the Village.

A.E. Keough Machine Shop

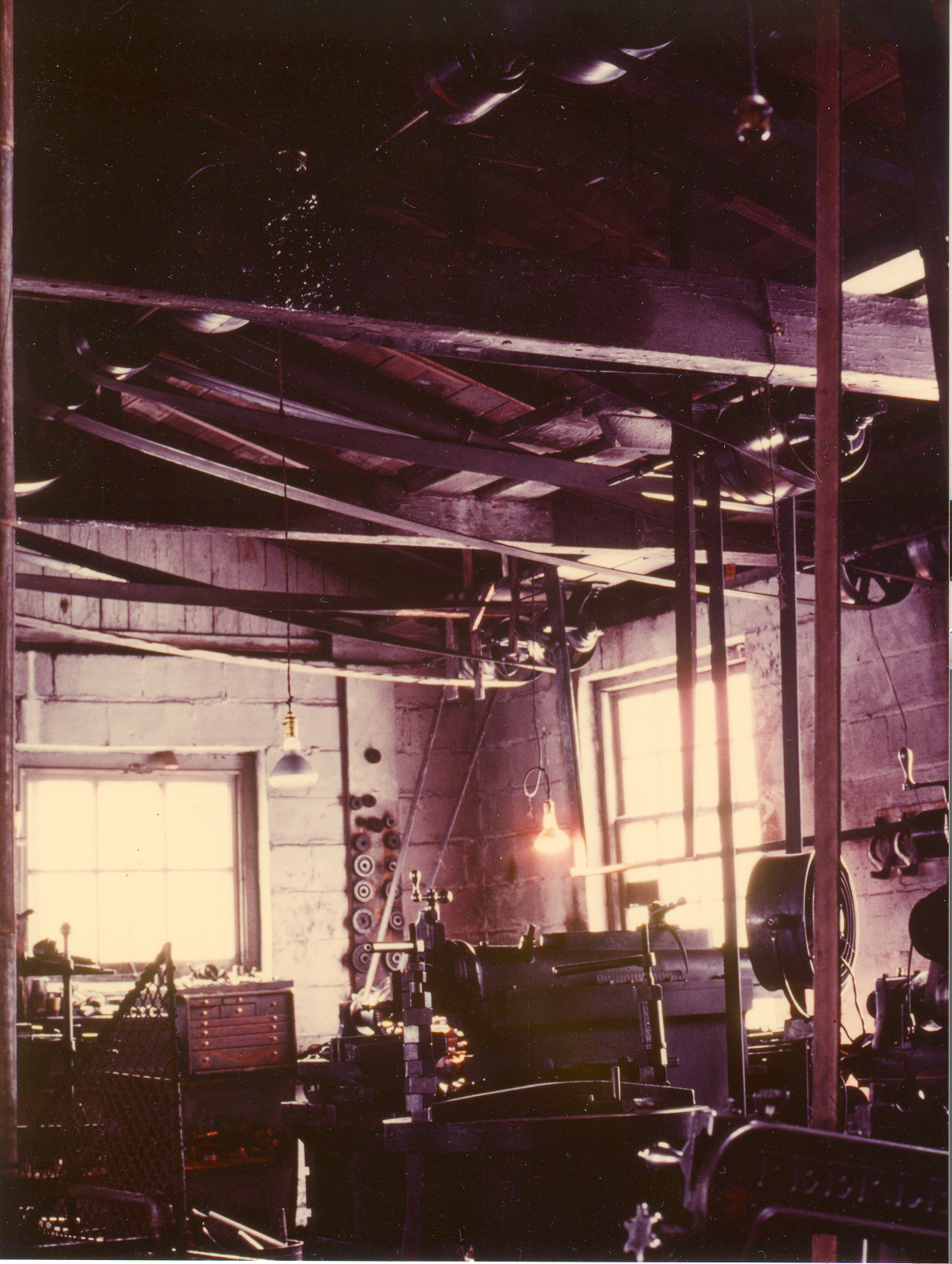

Machine shops in urban centres marked the move away from blacksmiths for metal working. Machine tools were faster, stronger, more accurate and more consistent than the work of a blacksmith. Machine shops could also work with a wide variety of metals, such as iron casting, steel, brass, and bronze in block, bar, shaft or tube form.

The purpose of machine shop equipment is to cut pieces of metal to the shape, size, and finish needed for a particular part of a product. The machine tool can provide greater accuracy, speed, and strength than the blacksmith can, and with less manual skill. The raw material of the shop includes iron castings, steel, brass, bronze, or other metals in the form of blocks, bars, shafting, or tubing. Each machine tool is designed to carry out a different variety of operations and, despite the large size of many jobs, can machine surfaces to within a thousandth of an inch of an inch of a required dimension.

It may be noted that the term “machine tool” does not include rolling mills used in a steel plant, a foundry which casts molten metal, sheet metal equipment, production equipment used in a factory, or forging equipment in which hot metal is hammered to shape. However, the A.E. Keough machine shop also did welding and, at one time, included a small blacksmith which undoubtedly shod a lot of horses.

In 1918, a Arthur Keough walked into the Warren Brothers Machine Shop, then located at 314 Talbot Street, looking for washing machine parts. When one of the owners offered him an apprenticeship, he enthusiastically agreed. In 1923, the Warren Brothers moved their business to the corner of Rectory Street and Hamilton Road, and in 1927 they erected a new building to house the shop. In 1945, after 27 years working in the Warren Brothers Machine Shop, Keough purchased the building for $4,707. When the A.E. Keough Machine Shop closed in 1979, Keough was still using the same turn of the century machinery which the Warren Brothers had used. The original shop at 109 Rectory Street has since been demolished, but the contents of Keough’s shop were donated to Fanshawe Pioneer Village in 1979. The central line shaft and pulleys that once powered Keough’s machinery are still visible inside.

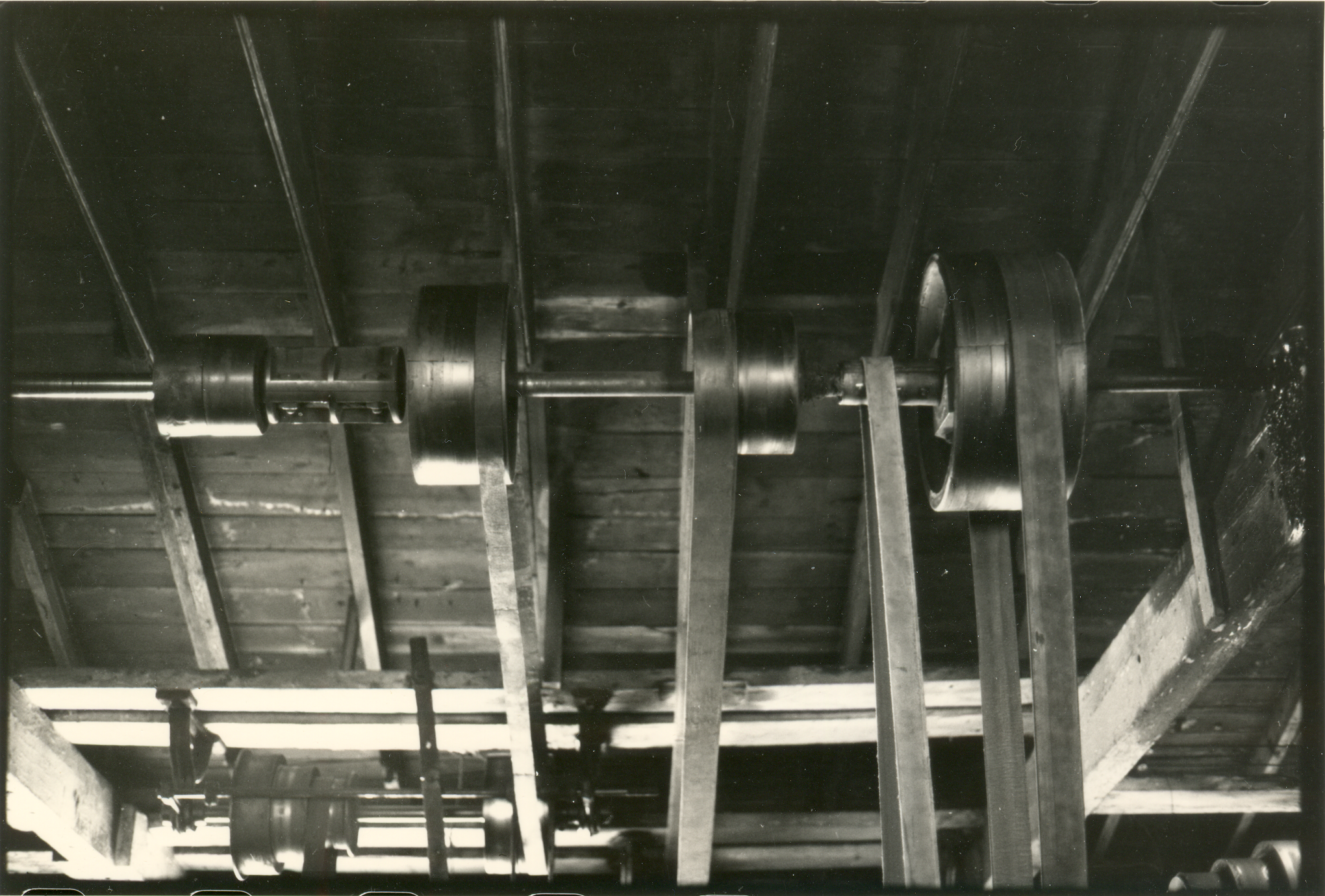

A line shaft is a power transmission system used before the widespread use of electric motors small enough to be connected directly to each piece of machinery. This Line shaft was used to distribute power from a large central power source, initially horses then steam, to machinery throughout the Keough Machine Shop.

The line shaft is suspended from the ceiling and runs the length of the building. One pulley on the shaft would receive the power from the parent line shaft. The other pulleys would supply power to each individual machine or to subsequent line shafts. In machine shops such as this, where there were a variety of machines with different orientations and power requirements, the system would appear erratic and inconsistent with many different shafting directions and pulley sizes.